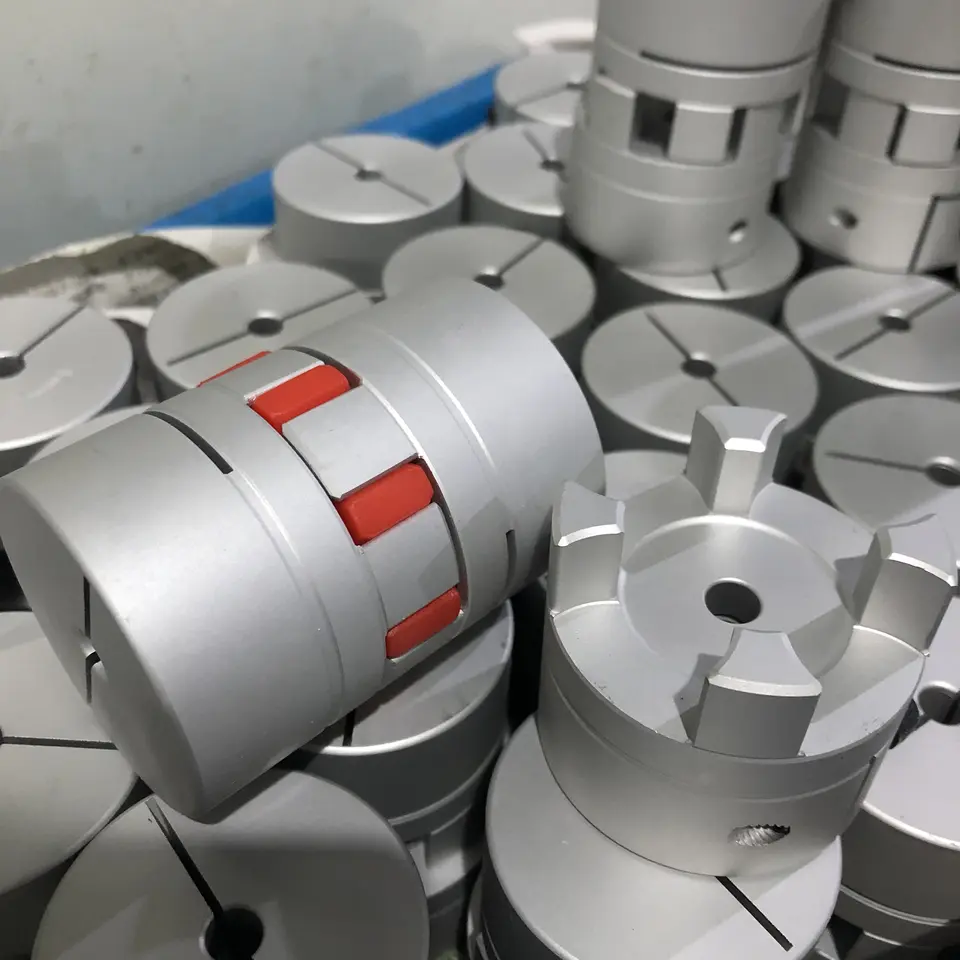

Product Description

1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111

| Item No. | φD | L | L1 | W | M | Tighten the strength(N.m) |

| SG7-11-30- | 30 | 50 | 18.5 | 13 | M3(4) | 1.2 |

| SG7-11-40- | 40 | 66 | 25 | 16 | M4(6) | 2.7 |

| SG7-11-55- | 55 | 78 | 30 | 18 | M5(4) | 6 |

| SG7-11-65- | 65 | 90 | 35 | 20 | M5(6) | 6 |

| SG7-11-80- | 80 | 114 | 45 | 24 | M6(8) | 10 |

| SG7-11-95- | 95 | 126 | 50 | 26 | M8(4) | 35 |

| SG7-11-105- | 105 | 140 | 56 | 28 | M8(4) | 35 |

111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111

| Item No. | Rated torque | Maximum Torque | Max Speed | Inertia Moment | N.m rad | Tilting Tolerance | End-play | Weight:(g) |

| SG7-11-30- | 7.4N.m | 14.8N.m | 20000prm | 8.7×10-4kg.m² | 510N.m/rad | 1.0c | +0.6mm | 50 |

| SG7-11-40- | 9.5N.m | 19N.m | 15000prm | 1.12×10-3kg.m² | 550N.m/rad | 1.0c | +0.8mm | 120 |

| SG7-11-55- | 34N.m | 68N.m | 13000prm | 4.5×10-3kg.m² | 1510N.m/rad | 1.0c | +0.8mm | 280 |

| SG7-11-65- | 95N.m | 190N.m | 10500prm | 9.1×10-3kg.m² | 2800N.m/rad | 1.0c | +0.8mm | 450 |

| SG7-11-80- | 135N.m | 270N.m | 8600prm | 1.9×10-2kg.m² | 3600N.m/rad | 1.0c | +1.0mm | 960 |

| SG7-11-95- | 230N.m | 460N.m | 7500prm | 2.2×10-2kg.m² | 4700N.m/rad | 1.0c | +1.0mm | 2310 |

| SG7-11-105- | 380N.m | 760N.m | 6000prm | 3.3×10-2kg.m² | 5800N.m/rad | 1.0c | +1.0mm | 3090 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Torque and Speed Ratings for Different Sizes of Jaw Couplings

The torque and speed ratings for jaw couplings vary depending on their size and design. Manufacturers typically provide specifications for different sizes of jaw couplings, and it's essential to select the appropriate coupling based on the specific requirements of the application. Here's how torque and speed ratings are determined for jaw couplings:

- Torque Rating: The torque rating of a jaw coupling is the maximum amount of torque it can transmit without causing failure. It is typically specified in Newton-meters (Nm) or inch-pounds (in-lb). Larger jaw couplings generally have higher torque ratings than smaller ones, as they can accommodate more substantial loads.

- Speed Rating: The speed rating of a jaw coupling refers to the maximum rotational speed at which it can operate efficiently and reliably. It is usually specified in revolutions per minute (RPM). Higher-speed applications may require jaw couplings designed to handle increased rotational velocities.

It's essential to carefully match the torque and speed requirements of the application with the appropriate jaw coupling size. Undersized couplings may result in premature failure, while oversized couplings might lead to reduced flexibility and increased wear. Manufacturers' catalogs or product datasheets provide detailed information on the torque and speed ratings for each coupling size, helping engineers and designers make informed decisions when selecting the right coupling for their specific needs.

Can jaw couplings be used in marine and automotive applications?

Yes, jaw couplings can be used in both marine and automotive applications, and they have proven to be effective in various scenarios within these industries. Here's how jaw couplings are utilized in marine and automotive settings:

Marine Applications:

In the marine industry, jaw couplings are commonly used to connect the engine to various components, such as propellers, pumps, generators, and auxiliary equipment. They offer several advantages that make them suitable for marine applications:

- Corrosion Resistance: Marine environments are exposed to saltwater and other corrosive elements. Jaw couplings made from materials such as stainless steel or other corrosion-resistant alloys can withstand these harsh conditions and ensure long-lasting performance.

- Misalignment Compensation: Vessel movement and hull flexing can lead to misalignment between the engine and driven components. Jaw couplings can accommodate both angular and parallel misalignment, ensuring efficient power transmission even in dynamic marine conditions.

- Vibration Damping: The elastomer spider in the jaw coupling absorbs vibrations generated by the engine and other equipment, contributing to smoother operation and reduced wear on the components.

- Compact Design: Space is often limited on boats and ships. Jaw couplings have a compact and lightweight design, making them suitable for applications with space constraints.

Automotive Applications:

In the automotive industry, jaw couplings are used in various applications, including power steering systems, engine-driven accessories, and HVAC blowers. They offer several benefits for automotive applications:

- Misalignment Compensation: Jaw couplings can handle small misalignments that can occur due to engine movements or assembly tolerances, ensuring reliable power transmission and reducing stress on the drivetrain.

- Vibration Damping: The elastomer spider in the jaw coupling dampens engine vibrations, contributing to a smoother and quieter ride for passengers.

- Compact and Lightweight: In modern vehicles, lightweight components are essential for fuel efficiency and overall performance. Jaw couplings' compact design and low inertia make them suitable for automotive applications.

- Cost-Effectiveness: Jaw couplings are often more cost-effective compared to some other coupling types, making them a popular choice for automotive applications where cost considerations are essential.

In conclusion, jaw couplings are versatile and can be successfully used in marine and automotive applications. Their ability to handle misalignment, dampen vibrations, and provide efficient power transmission makes them reliable components in various dynamic and demanding environments.

Safety Considerations When Using Jaw Couplings in Rotating Machinery

While jaw couplings are generally safe to use in rotating machinery, there are some important safety considerations to keep in mind to ensure safe and reliable operation:

- Proper Installation: Correct installation is crucial for the safe functioning of jaw couplings. The coupling should be mounted precisely in alignment with the shafts to prevent misalignment and minimize stress on the components.

- Regular Maintenance: Regular inspection and maintenance are essential to identify signs of wear, misalignment, or damage. Any issues should be addressed promptly to prevent potential failures that may compromise safety.

- Load Capacity: Ensure that the selected jaw coupling has an adequate load capacity for the specific application. Overloading the coupling can lead to premature failure and safety risks.

- Operating Speed: Be mindful of the operating speed limitations of the jaw coupling. Operating the coupling beyond its maximum rated speed may result in excessive wear and potential hazards.

- Environmental Factors: Consider the environmental conditions in which the jaw coupling will operate. Extreme temperatures, humidity, or corrosive substances may impact the coupling's performance and longevity.

- Emergency Shutdown: Implement an emergency shutdown procedure to quickly stop the machinery in case of any unexpected issues or safety concerns.

- Guarding and Enclosure: Depending on the application, consider using protective guarding or enclosures to prevent accidental contact with rotating components and ensure operator safety.

- Compliance with Standards: Follow industry standards and regulations relevant to the specific application to ensure compliance and adherence to safety guidelines.

By adhering to these safety considerations, operators and maintenance personnel can help minimize the risk of accidents, protect personnel from potential hazards, and ensure the reliable and safe operation of rotating machinery with jaw couplings.

editor by CX 2024-01-25