Product Description

Excellent Quality of Our Sintered Powder Metallurgy parts

Our company is producing and exporting wide variety of automotive parts, textile machine, sewing machine, gasoline generator, power tools, oil pump rotor, clutch, oilless bearing, bushings, clutch and so many others with high quality. We can support various powder metallurgy parts including iron, copper, stainless steel and alloy materials based with high quality and reasonable prices. We can also make different sizes and models as the customers' desired orders.

Over 200 workers are supporting and producing under the control of 3 Professional Engineers who has 20 years experiences in this production. We are always receiving customers' feedbacks and changing the supplier products as the needs of our customers by special service team.

If you are interested in our products, please do not hesitate to contact us.

Our Products Special Features,

1) Our products passed TS16949 ISO-9001: 2000 quality management system verification

2) Material: Steel, copper, brass, aluminum, Titanium

3) Equipment: CNC lathe, CNC milling machine, CNC high-speed engraving machine, Common machines, laser engraving machines, metal injection machine

4) Precision machining capability:

5) Advanced workmanship, fitting tool, fixture, cutting tool

6) Parts can be supplied according to customers' drawings or samples.

7) 2D/3D drawings or samples are welcome!

8). Best quality, competitive price, shortest delivery time and good service.

| Place of origin: | ZHangZhoug, China |

| Brand Name: | HangZhou Xihu (West Lake) Dis. Powder Metallurgy Co.,Ltd |

| Type: | Powder metallurgy sintering |

| Surface finish | e-coating, electroplating and black oxygen |

| Measuring method | 3D system, High-lubrication, high-density and high-strength |

| Inspection equipment | Torsion test, voltage feedback test, HRC density test, lifting test and salt spray resistant test and more |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron, stainless steel, copper, Alloy |

| Application: | Automotive parts, power tools, stainless steel, bushings, clutches and so many others |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgy, CNC Machining |

| Powder Metallurgy: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

Powder Metallurgy Component Production Process

A trained, qualified, and dedicated work force

1) Engineering is our strength - we will help your designers convert your parts to cost-effective powdered metal parts.

2) Every employee is trained to a standard of excellence.

Quality is designed into the process

1) Consistent and committed attitude to quality first.

Critical characteristics are measured and controlled using the latest statistical methods

1) Quality is always the first priority.

2) Our subcontractors are held to the same high standards.

OUR FACTORY

Certification

FAQ

1. When can I get the price?

Re: The quotation should be given within 24 hours.

2. How to get the best price from Xihu (West Lake) Dis. Company?

Re: The bulk order price can be negotiated.

We will quote the latest best price according to the customer final purchase list.

3. How can I get a sample to check your quality?

Re: Most sample could be free for you, you need just to pay the freight to your place.

Usually, the sample will be sent within 1 week. It depends on the stock.

4. Can you do the packages as we need?

Yes. Surely! We can do OEM Package for you.

We can design the package as your desired request.

5. What is your MOQ?

Re: For the spare parts and accessories, it would depend on the detailed products.

6. What is your delivery time?

Re: Normally 15-30 days for our products to your order placed.

Generally speaking, we suggest that you start inquiry 2 months before the date you would like to get the products at your country.

7. What is your payment?

Re: We accept T/T and L/C, D/P, Western Union, PayPal.

You can choose the 1 which is the most convenient or cost effective for you.

8. What's your transportation?

Re: By land, by air, by sea

If anything else that you want to know, please contact us.

Thanks for reading our introduction!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

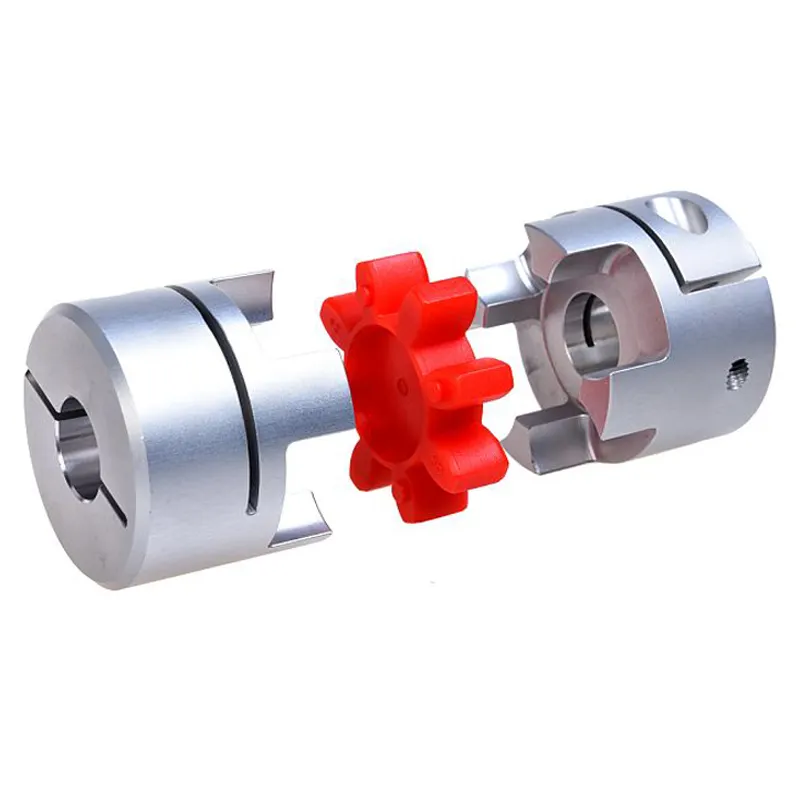

Usage of Jaw Couplings for Motor-to-Shaft and Shaft-to-Shaft Connections

Jaw couplings are versatile components that can be used for both motor-to-shaft and shaft-to-shaft connections in mechanical power transmission systems. Their design and features make them suitable for various applications:

- Motor-to-Shaft Connection: When connecting a motor to a driven shaft, jaw couplings are commonly used to transmit torque from the motor to the driven equipment. The motor's shaft is inserted into one side of the jaw coupling, and the driven shaft is inserted into the other side. The elastomeric spider element in the coupling provides a flexible connection that accommodates misalignment and dampens vibrations, ensuring smooth power transmission from the motor to the driven shaft.

- Shaft-to-Shaft Connection: In cases where two shafts need to be connected directly, without a motor or other driving element, jaw couplings can be used for shaft-to-shaft connections. Both shafts are inserted into the respective sides of the jaw coupling, and the elastomeric spider element bridges the gap between them. This enables torque transfer between the two shafts while compensating for any misalignment that may exist.

Whether used for motor-to-shaft or shaft-to-shaft connections, jaw couplings offer the same advantages, including misalignment compensation, vibration dampening, and backlash-free operation (depending on the design). These features make them suitable for various applications across different industries, where reliable and efficient power transmission is essential.

What are the common signs of wear and failure in jaw couplings?

Jaw couplings are reliable components, but like any mechanical part, they can experience wear and eventually fail if not properly maintained or replaced when necessary. Here are some common signs of wear and failure to look out for in jaw couplings:

- Excessive Vibration: Increased vibration during operation may indicate wear in the elastomer spider or misalignment between the coupling hubs. Excessive vibration can lead to further damage and should be addressed promptly to prevent more significant issues.

- Abnormal Noise: Unusual noises, such as rattling, clanking, or squeaking sounds, can indicate wear, misalignment, or damage in the jaw coupling. A well-functioning jaw coupling should operate smoothly and quietly.

- Visible Cracks or Damage: Inspect the jaw coupling regularly for any visible cracks, tears, or damage to the elastomer spider or coupling hubs. Cracks in the elastomer can lead to reduced torque transmission and compromise the coupling's performance.

- Loose or Displaced Spider: A loose or displaced elastomer spider may result from wear or improper installation. The spider should fit securely between the coupling hubs. Any sign of misalignment or gaps in the spider indicates potential wear or failure.

- Increased Heat: Excessive heat generation in the jaw coupling could indicate high levels of friction or misalignment, leading to wear on the elastomer spider. Elevated temperatures can accelerate wear and shorten the coupling's lifespan.

- Shaft Misalignment: If you notice misalignment between the connected shafts, it can be a sign that the jaw coupling is no longer compensating for misalignment properly. This can lead to increased stress on the shafts and coupling components.

- Reduced Performance: A jaw coupling nearing the end of its service life may experience reduced torque transmission and compromised rotational speed control. As the elastomer spider wears, the coupling's ability to transmit torque efficiently diminishes.

- Unexpected Downtime: Frequent unexpected shutdowns or downtime may indicate coupling failure. Sudden coupling failure can lead to costly equipment damage and unplanned production halts.

It is essential to conduct regular maintenance and inspections to detect these signs of wear and failure early. Preventive measures such as proper lubrication, alignment checks, and timely replacement of worn elastomer spiders can extend the life of the jaw coupling and prevent unexpected failures.

If any of these signs are observed, it is advisable to consult coupling manufacturers or maintenance professionals for a thorough assessment and appropriate corrective actions.

What is a Jaw Coupling and How Does It Work?

A jaw coupling is a type of mechanical coupling used to connect two shafts in machinery. It is designed to transmit torque while compensating for shaft misalignments and dampening vibrations. The coupling consists of two hubs with three curved jaws each and an elastomeric spider placed between them.

The working principle of a jaw coupling is based on the flexibility of the elastomeric spider. When the two hubs are brought together, the spider gets compressed between them. The curved shape of the jaws allows the spider to flex, accommodating angular and axial misalignments between the shafts.

During operation, when torque is applied to one shaft, it is transmitted through the spider to the other shaft, enabling power transmission. The elastomeric material of the spider also acts as a damping element, reducing vibrations and shock loads in the system.

Jaw couplings are commonly used in various applications, such as pumps, compressors, conveyors, and other power transmission systems. Their simple design, ease of installation, and ability to handle misalignments make them popular choices for connecting rotating shafts in machinery.

editor by CX 2024-03-29