Product Description

Product Description

|

Product name |

Chain coupling |

|||

|

Material |

Carbon steel material |

|||

|

Structure |

Roller chain+sprocket+cover |

|||

|

Size |

KC3012, KC4012, KC4014, KC4016, KC5014, KC5016, KC5018, KC6018, KC6571, KC6571, KC8018, KC8571, KC8571, KC1571, KC12018, KC12571, KC16018, KC16571, KC20018, KC20571, KC24026 |

|||

|

Other type |

Flexible coupling |

|||

|

Application |

Shaft transmission |

|||

|

Feature |

High performance, light weight, convenient assembly |

|||

Packaging & Shipping

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

"Credibility Supremacy, and Customer First"

3. Our Promise:

"High quality products, and Excellent Service"

4. Our Value:

"Being Honesty, Doing the Best, and Long-lasting Development"

5. Our Aim:

"Develop to be a leader in the power transmission parts industry in the world"

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

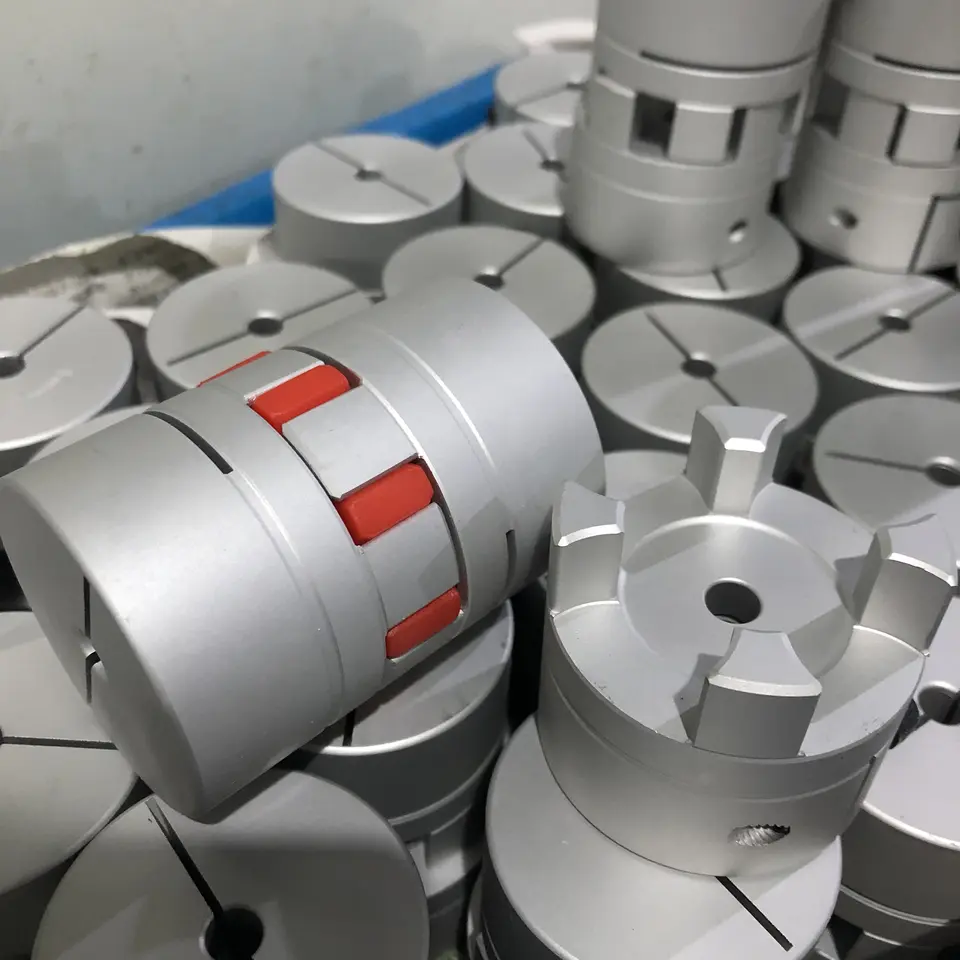

Differences between Elastomer and Metallic Jaw Coupling Designs

Jaw couplings are available in two primary designs: elastomer jaw couplings and metallic jaw couplings. Each design has its own set of characteristics and advantages:

- Elastomer Jaw Couplings: Elastomer jaw couplings, also known as flexible jaw couplings, feature an elastomeric spider element that sits between the two hubs. This spider element is typically made of materials like polyurethane, rubber, or other flexible polymers. The elastomeric material provides the coupling with flexibility, allowing it to compensate for shaft misalignment, angular, parallel, and axial, as well as dampen vibrations and shocks. Elastomer jaw couplings are popular for their ability to protect connected equipment from mechanical stresses and enhance overall system performance. They are commonly used in applications where some misalignment is expected or in systems with shock loads and vibrations. Additionally, elastomer jaw couplings are known for their relatively lower cost compared to metallic designs.

- Metallic Jaw Couplings: Metallic jaw couplings, also known as rigid jaw couplings, are constructed entirely from metal, usually steel or aluminum. Unlike elastomer couplings, metallic jaw couplings do not have an elastomeric spider element and offer a more rigid connection between the two hubs. As a result, they are less forgiving of misalignment and do not provide the same level of vibration dampening as elastomer couplings. However, metallic jaw couplings offer higher torque capacity and are better suited for applications where precise shaft alignment is critical. They are commonly used in systems that require high torque transmission and minimal torsional flexibility. Additionally, metallic jaw couplings are well-suited for environments with high temperatures or exposure to chemicals, as they can withstand harsher conditions compared to elastomer designs.

The choice between elastomer and metallic jaw couplings depends on the specific requirements of the application. If flexibility, misalignment compensation, and vibration dampening are crucial, elastomer jaw couplings are preferred. On the other hand, when high torque transmission, precise alignment, and durability in challenging environments are needed, metallic jaw couplings are the better option.

What are the temperature and environmental limitations of jaw couplings?

Jaw couplings, like many mechanical components, have temperature and environmental limitations that need to be considered for proper operation and longevity. These limitations are determined by the materials used in the construction of the jaw coupling and the specific operating conditions it will encounter. Here are some of the common temperature and environmental limitations of jaw couplings:

- Temperature Limitations: The operating temperature range of a jaw coupling depends on the materials used for its components, particularly the elastomer spider. Standard elastomers, such as polyurethane or nitrile rubber, are commonly used in jaw couplings and have typical temperature limits of approximately -40°C to 80°C (-40°F to 176°F). For more extreme temperature requirements, specialized elastomers with higher or lower temperature resistance may be available. It is essential to consider the ambient temperature and the temperature generated during equipment operation to ensure the jaw coupling remains within its temperature limits.

- Environmental Limitations: Jaw couplings can be affected by various environmental factors, and their performance might be influenced by the presence of certain substances. Some environmental limitations to consider include:

- Chemical Exposure: Exposure to harsh chemicals, oils, solvents, or corrosive substances can degrade the elastomer spider and other components of the jaw coupling. Specialized coatings or alternative materials may be required for applications with aggressive chemical environments.

- Dust and Debris: Excessive dust, dirt, or debris in the operating environment can accumulate on the coupling's surfaces and affect its performance. Regular cleaning and maintenance may be necessary to prevent buildup and ensure optimal operation.

- Moisture and Water: Some jaw couplings may not be suitable for applications where they are continually exposed to moisture or submerged in water. In such cases, water-resistant or corrosion-resistant materials may be necessary.

- Shock and Vibration: High levels of shock and vibration in the operating environment can accelerate wear and reduce the coupling's lifespan. Selecting a robust coupling design and appropriate materials can help mitigate the effects of these factors.

- Electrically Conductive Environments: In some applications, it is essential to consider the electrical conductivity of the coupling's materials, especially when dealing with sensitive electronic equipment.

It is crucial to consult the manufacturer's specifications and guidelines to ensure that the selected jaw coupling is suitable for the specific temperature and environmental conditions of the intended application. Proper maintenance, periodic inspections, and adhering to recommended operating parameters can extend the life and performance of the jaw coupling in a given environment.

Can Jaw Couplings Accommodate High Torque and High-Speed Applications?

Jaw couplings are versatile and can handle a wide range of torque and speed requirements. However, their suitability for high torque and high-speed applications depends on the specific design and material of the coupling.

Advancements in jaw coupling technology and the use of high-strength materials, such as steel and aluminum, have significantly improved their performance capabilities. For many industrial applications, jaw couplings can efficiently accommodate high torque and high-speed requirements.

When selecting a jaw coupling for high torque and high-speed applications, consider the following factors:

- Coupling Size: Choose a jaw coupling size that matches the torque and speed requirements of the application. Larger couplings with bigger spider elements can handle higher torque loads.

- Material: Opt for jaw couplings made from robust materials like steel or aluminum, which can withstand higher torque and speed without compromising structural integrity.

- Design: Some jaw coupling designs are better suited for high torque applications, offering increased torque capacity and better performance under heavy loads.

- Service Factor: Consider the service factor, which accounts for peak or intermittent loads, to ensure the selected jaw coupling can handle temporary torque spikes.

It's essential to consult with coupling manufacturers or industry experts to determine the most suitable jaw coupling for specific high torque and high-speed applications. Properly sized and selected jaw couplings can provide reliable and efficient power transmission in demanding industrial scenarios.

editor by CX 2024-05-09