Product Description

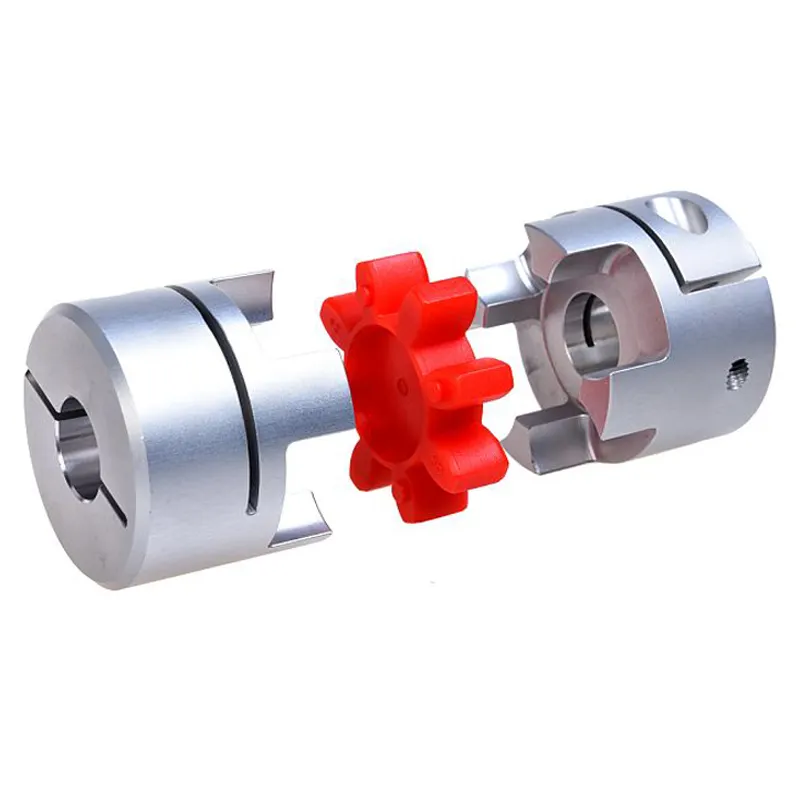

Customized Forestry machinery and equipment jaw couplings,jaw spider coupling,curved jaw coupling

Features

1. Split in half design for simple installation, maintaining free

2. High misalignment capacity

3. Facility protection for a twirl, twist, impact, and abrasion

4. No lubrication for polyurethane flex element

5. Available for bore-to-size hubs and taper lock bushes

6. Low noise

Product Description

|

Size |

Type |

A |

B |

D |

E |

Standard |

Metric bore |

Inch bore |

||

|

bore |

Min |

Max |

Min |

Max |

||||||

| L035 |

1 |

16 |

20.5 |

6.6 |

/ |

3 |

3 |

8 |

1/8" |

3/8" |

|

L050 |

1 |

28 |

43.2 |

15.6 |

/ |

6 |

6 |

15 |

3/16" |

5/8" |

|

L070 |

1 |

35 |

50.8 |

19 |

/ |

9 |

9 |

19 |

3/16" |

3/4" |

|

L075 |

1 |

45 |

54.7 |

21 |

/ |

9 |

9 |

25 |

3/16" |

1" |

|

L090 |

1 |

54 |

54.7 |

21 |

/ |

9 |

9 |

28 |

3/16" |

1 1/8" |

|

L095 |

1 |

54 |

63.7 |

25.5 |

/ |

9 |

9 |

28 |

3/8" |

1 1/8" |

|

L099 |

1 |

64.5 |

72.5 |

27 |

/ |

12 |

12 |

35 |

7/16" |

1 3/8" |

|

L100 |

1 |

64.5 |

88.5 |

35 |

/ |

12 |

12 |

35 |

7/16" |

1 3/8" |

|

L110 |

1 |

85 |

108 |

43 |

/ |

15 |

15 |

48 |

1/2" |

1 7/8" |

|

L150 |

1 |

96 |

115.4 |

45 |

/ |

15 |

15 |

48 |

5/8" |

1 7/8" |

|

L190 |

2 |

115 |

133.4 |

54 |

101.6 |

19 |

19 |

55 |

5/8" |

2 1/4" |

|

L225 |

2 |

127 |

153.4 |

64 |

108 |

19 |

19 |

65 |

3/4" |

2 5/8" |

Related Products

Company Profile

FAQ

Q: How to ship to us?

A: It is available by air, by sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Usage of Jaw Couplings for Motor-to-Shaft and Shaft-to-Shaft Connections

Jaw couplings are versatile components that can be used for both motor-to-shaft and shaft-to-shaft connections in mechanical power transmission systems. Their design and features make them suitable for various applications:

- Motor-to-Shaft Connection: When connecting a motor to a driven shaft, jaw couplings are commonly used to transmit torque from the motor to the driven equipment. The motor's shaft is inserted into one side of the jaw coupling, and the driven shaft is inserted into the other side. The elastomeric spider element in the coupling provides a flexible connection that accommodates misalignment and dampens vibrations, ensuring smooth power transmission from the motor to the driven shaft.

- Shaft-to-Shaft Connection: In cases where two shafts need to be connected directly, without a motor or other driving element, jaw couplings can be used for shaft-to-shaft connections. Both shafts are inserted into the respective sides of the jaw coupling, and the elastomeric spider element bridges the gap between them. This enables torque transfer between the two shafts while compensating for any misalignment that may exist.

Whether used for motor-to-shaft or shaft-to-shaft connections, jaw couplings offer the same advantages, including misalignment compensation, vibration dampening, and backlash-free operation (depending on the design). These features make them suitable for various applications across different industries, where reliable and efficient power transmission is essential.

How does a jaw coupling deal with backlash and torsional stiffness?

A jaw coupling addresses backlash and torsional stiffness through its unique design features and choice of materials. Backlash is the amount of free play or clearance between the coupling components, while torsional stiffness refers to the resistance of the coupling to torsional or twisting forces. Here's how a jaw coupling deals with these aspects:

- Backlash: Jaw couplings are designed to minimize backlash by ensuring a close fit between the elastomer spider and the jaws of the coupling hubs. The elastomer spider acts as a flexible intermediary that fills the space between the mating jaws, reducing any free play between them. This close fit reduces backlash and provides a more precise and responsive power transmission, especially in reversing or intermittent motion applications.

- Torsional Stiffness: Torsional stiffness is achieved in jaw couplings by using materials that provide a balance between flexibility and rigidity. The elastomer spider in the coupling offers some flexibility, allowing it to absorb vibrations and dampen shocks. However, to ensure adequate torsional stiffness, the coupling hubs are usually made from sturdier materials like steel or aluminum. The choice of elastomer material and its geometry also influences the torsional stiffness of the coupling. Some applications may require coupling designs with higher torsional stiffness to maintain the accuracy and stability of the system, while others may benefit from more flexible couplings that can accommodate misalignments and shock loads. Overall, the combination of the elastomer's flexibility and the coupling hub's rigidity results in a coupling with a balanced torsional stiffness that can meet the specific needs of the application.

In summary, a jaw coupling minimizes backlash by providing a close fit between the coupling components, and it achieves torsional stiffness by using a combination of flexible elastomer materials and rigid coupling hubs. These design considerations make jaw couplings suitable for a wide range of applications that require reliable power transmission, precise motion control, and the ability to handle misalignments and shocks.

Safety Considerations When Using Jaw Couplings in Rotating Machinery

While jaw couplings are generally safe to use in rotating machinery, there are some important safety considerations to keep in mind to ensure safe and reliable operation:

- Proper Installation: Correct installation is crucial for the safe functioning of jaw couplings. The coupling should be mounted precisely in alignment with the shafts to prevent misalignment and minimize stress on the components.

- Regular Maintenance: Regular inspection and maintenance are essential to identify signs of wear, misalignment, or damage. Any issues should be addressed promptly to prevent potential failures that may compromise safety.

- Load Capacity: Ensure that the selected jaw coupling has an adequate load capacity for the specific application. Overloading the coupling can lead to premature failure and safety risks.

- Operating Speed: Be mindful of the operating speed limitations of the jaw coupling. Operating the coupling beyond its maximum rated speed may result in excessive wear and potential hazards.

- Environmental Factors: Consider the environmental conditions in which the jaw coupling will operate. Extreme temperatures, humidity, or corrosive substances may impact the coupling's performance and longevity.

- Emergency Shutdown: Implement an emergency shutdown procedure to quickly stop the machinery in case of any unexpected issues or safety concerns.

- Guarding and Enclosure: Depending on the application, consider using protective guarding or enclosures to prevent accidental contact with rotating components and ensure operator safety.

- Compliance with Standards: Follow industry standards and regulations relevant to the specific application to ensure compliance and adherence to safety guidelines.

By adhering to these safety considerations, operators and maintenance personnel can help minimize the risk of accidents, protect personnel from potential hazards, and ensure the reliable and safe operation of rotating machinery with jaw couplings.

editor by CX 2024-01-15