Product Description

JMII Type Diaphragm Coupling(JB/T9147-1999)

JMII Elastic Diaphragm Coupling belong to JM series diaphragm couplings. They are made up of several groups of diaphragms (stainless steel thin wrench), and bolts are interlaced with 2 halves of couplings. Each diaphragm is made up of several sheets. The diaphragm is divided into connecting rod type and whole shape with different shapes. Its elastic deformation is used to compensate the relative displacement of the 2 axes, and it is a high performance flexible coupling of metal elastic elements. No lubrication, compact structure, high strength, long service life, no rotation clearance, no influence on temperature and oil pollution, it has the characteristics of acid resistance, alkali resistance and corrosion resistance.

JMII Type Diaphragm Coupling Main Dimension(JB/T9147-1999)

| Type | Nominal torque Tn |

Peak torque Tmax |

Max Speed nmax |

Bore Diameter d,d1 |

Bore length | D | D1 | t | Torsional rigidity×106 | Mass | Rotary inertia |

||

| J1 type | Y type |

L (recommend) |

|||||||||||

| L | |||||||||||||

| N·m | N·m | r·min-1 | mm | N·m/rad | kg | kg·m2 | |||||||

| JMII1 | 40 | 63 | 10700 | 14 | 27 | 32 | 35 | 80 | 39 | 8±0.2 | 0.37 | 0.9 | 0.0005 |

| 16,18,19 | 30 | 42 | |||||||||||

| 20,22,24 | 38 | 52 | |||||||||||

| 25,28 | 44 | 62 | |||||||||||

| JMII2 | 63 | 100 | 9300 | 20,22,24 | 38 | 52 | 40 | 92 | 53 | 0.45 | 1.4 | 0.0011 | |

| 25,28 | 44 | 62 | |||||||||||

| 30,32,35,38 | 60 | 82 | |||||||||||

| JMII3 | 100 | 200 | 8400 | 25,28 | 44 | 62 | 45 | 102 | 63 | 0.56 | 2.1 | 0.002 | |

| 30,32,35,38 | 60 | 82 | |||||||||||

| 40,42,45 | 84 | 112 | |||||||||||

| JMII4 | 250 | 400 | 6700 | 30,32,35,38 | 60 | 82 | 55 | 128 | 77 | 11±0.3 | 0.81 | 4.2 | 0.006 |

| 40,42,45,48,50,55 | 84 | 112 | |||||||||||

| JMII5 | 500 | 800 | 5900 | 35,38 | 60 | 82 | 65 | 145 | 91 | 1.2 | 6.4 | 0.012 | |

| 40,42,45,48,50,55,56 | 84 | 112 | |||||||||||

| 60,63,65 | 107 | 142 | |||||||||||

| JMII6 | 800 | 1250 | 5100 | 40,42,45,48,50,55,56 | 84 | 112 | 75 | 168 | 105 | 14±0.3 | 1.42 | 9.6 | 0.571 |

| 60,63,65,70,71,75 | 107 | 142 | |||||||||||

| JMII7 | 1000 | 2000 | 4750 | 45,48,50,55,56 | 84 | 112 | 80 | 180 | 112 | 15±0.4 | 1.9 | 12.5 | 0.0365 |

| 60,63,65,70,71,75 | 107 | 142 | |||||||||||

| 80 | 132 | 172 | |||||||||||

| JMII8 | 1600 | 3150 | 4300 | 50,55,56 | 84 | 112 | 200 | 120 | 2.35 | 15.5 | 0.057 | ||

| 60,63,65,70,71,75 | 107 | 142 | |||||||||||

| 80,85 | 132 | 172 | |||||||||||

| JMII9 | 2500 | 4000 | 4200 | 55,56 | 84 | 112 | 205 | 120 | 20±0.4 | 2.7 | 16.5 | 0.065 | |

| 60,63,65,70,71,75 | 107 | 142 | |||||||||||

| 80,85 | 132 | 172 | |||||||||||

| JMII10 | 3150 | 5000 | 4000 | 55,56 | 84 | 112 | 90 | 215 | 128 | 20±0.4 | 3.02 | 19.5 | 0.083 |

| 60,63,65,70,71,75 | 107 | 142 | |||||||||||

| 80,85,90 | 132 | 172 | |||||||||||

| JMII11 | 4000 | 6300 | 3650 | 60,63,65,70,71,75 | 107 | 142 | 100 | 235 | 132 | 23±0.5 | 3.46 | 25 | 0.131 |

| 80,85,90,95 | 132 | 172 | |||||||||||

| JMII12 | 5000 | 8000 | 3400 | 63,65,70,71,75 | 107 | 142 | 250 | 145 | 3.67 | 30 | 0.174 | ||

| 80,85,90,95 | 132 | 172 | |||||||||||

| 100 | 167 | 212 | |||||||||||

| JMII13 | 6300 | 10000 | 3200 | 63,65,70,71,75 | 107 | 142 | 110 | 270 | 155 | 5.2 | 36 | 0.239 | |

| 80,85,90,95 | 132 | 172 | |||||||||||

| 100,110 | 167 | 212 | |||||||||||

| JMII14 | 8000 | 12500 | 2850 | 65,70,71,75 | 107 | 142 | 115 | 300 | 162 | 27±0.6 | 7.8 | 45 | 0.38 |

| 80,85,90,95 | 132 | 172 | |||||||||||

| 100,110 | 167 | 212 | |||||||||||

| JMII15 | 10000 | 16000 | 2700 | 70,71,75 | 107 | 142 | 125 | 320 | 176 | 8.43 | 55 | 0.5 | |

| 80,85,90,95 | 132 | 172 | |||||||||||

| 100,110,120,125 | 167 | 212 | |||||||||||

| JMII16 | 12500 | 20000 | 2450 | 75 | 107 | 142 | 140 | 350 | 186 | 32±0.7 | 10.23 | 75 | 0.85 |

| 80,85,90,95 | 132 | 172 | |||||||||||

| 100,110,120,125 | 167 | 212 | |||||||||||

| 130 | 202 | 252 | |||||||||||

| JMII17 | 16000 | 25000 | 2300 | 80,85,90,95 | 132 | 172 | 145 | 370 | 203 | 10.97 | 85 | 1.1 | |

| 100,110,120,125 | 167 | 212 | |||||||||||

| 130,140 | 202 | 252 | |||||||||||

| JMII18 | 20000 | 31500 | 2150 | 90,95 | 132 | 172 | 165 | 400 | 230 | 13.07 | 115 | 1.65 | |

| 100,110,120,125 | 167 | 212 | |||||||||||

| 130,140,150 | 202 | 252 | |||||||||||

| 160 | 242 | 302 | |||||||||||

| JMII19 | 25000 | 40000 | 1950 | 100,110,120,125 | 167 | 212 | 175 | 440 | 245 | 38±0.9 | 14.26 | 150 | 2.69 |

| 130,140,150 | 202 | 252 | |||||||||||

| 160,170 | 242 | 302 | |||||||||||

| JMII20 | 31500 | 50000 | 1850 | 110,120,125 | 167 | 212 | 185 | 460 | 260 | 22.13 | 170 | 3.28 | |

| 130,140,150 | 202 | 252 | |||||||||||

| 160,170,180 | 242 | 302 | |||||||||||

| JMII21 | 35500 | 56000 | 1800 | 120,125 | 167 | 212 | 200 | 480 | 280 | 38±0.9 | 23.7 | 200 | 4.28 |

| 130,140,150 | 202 | 252 | |||||||||||

| 160,170,180 | 242 | 302 | |||||||||||

| 190,200 | 282 | 352 | |||||||||||

| JMII22 | 40000 | 63000 | 1700 | 130,140,150 | 202 | 252 | 210 | 500 | 295 | 24.6 | 230 | 5.18 | |

| 160,170,180 | 242 | 302 | |||||||||||

| 190,200 | 282 | 352 | |||||||||||

| JMII23 | 50000 | 80000 | 1600 | 140,150 | 202 | 252 | 220 | 540 | 310 | 44±1 | 29.71 | 275 | 7.7 |

| 160,170,180 | 242 | 302 | |||||||||||

| 190,200,220 | 282 | 352 | |||||||||||

| JMII24 | 63000 | 10000 | 1450 | 150 | 202 | 252 | 240 | 600 | 335 | 50±1.2 | 32.64 | 380 | 9.3 |

| 160,170,180 | 242 | 302 | |||||||||||

| 190,200,220 | 282 | 352 | |||||||||||

| 240 | 330 | 410 | |||||||||||

| JMII25 | 80000 | 125000 | 1400 | 160,170,180 | 242 | 302 | 255 | 620 | 350 | 37.69 | 410 | 15.3 | |

| 190,200,220 | 282 | 352 | |||||||||||

| 240,250 | 330 | 410 | |||||||||||

| JMII26 | 90000 | 140000 | 1300 | 160 | 242 | 302 | 275 | 660 | 385 | 50.43 | 510 | 20.9 | |

| 190,200,220 | 282 | 352 | |||||||||||

| 240,250,260 | 330 | 410 | |||||||||||

| JMII27 | 112000 | 180000 | 1200 | 190,200,220 | 282 | 352 | 295 | 720 | 410 | 60±1.4 | 71.51 | 620 | 32.4 |

| 240,250,260 | 330 | 410 | |||||||||||

| 280 | 380 | 470 | |||||||||||

| JMII28 | 140000 | 20000 | 1150 | 220 | 282 | 352 | 300 | 740 | 420 | 93.37 | 680 | 36 | |

| 240,250,260 | 330 | 410 | |||||||||||

| 280,300 | 380 | 470 | |||||||||||

| JMII29 | 160000 | 224000 | 1100 | 240,250,260 | 330 | 410 | 320 | 770 | 450 | 114.53 | 780 | 43.9 | |

| 280,300,320 | 380 | 470 | |||||||||||

| JMII30 | 180000 | 280000 | 1050 | 250,260 | 330 | 410 | 350 | 820 | 490 | 130.76 | 950 | 60.5 | |

| 280,300,320 | 380 | 470 | |||||||||||

| 340 | 450 | 550 | |||||||||||

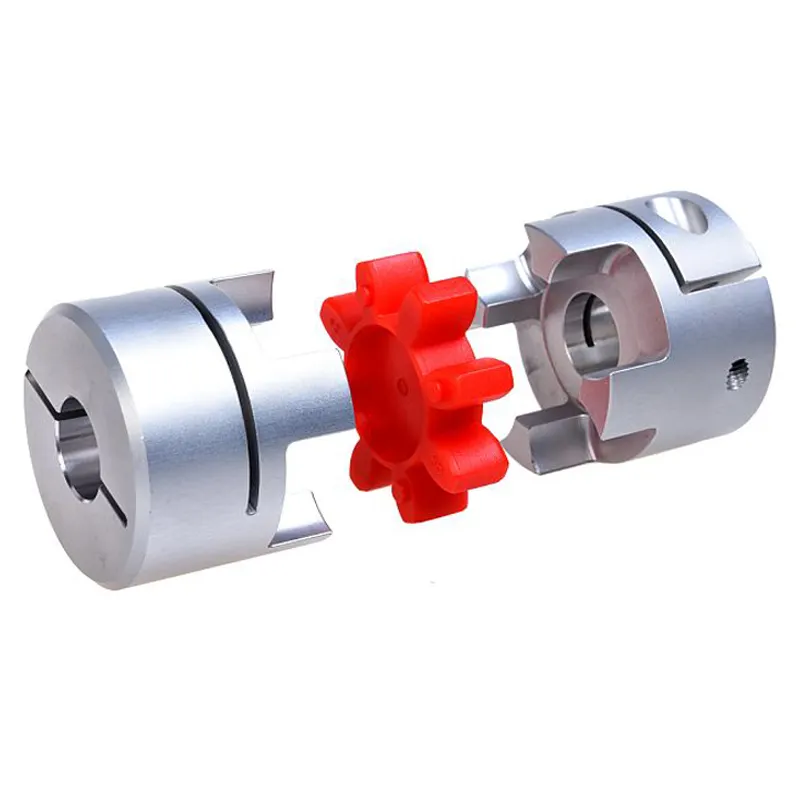

Product Display

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.

♦Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artworks.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What's your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Using Jaw Couplings in Hydraulic and Pneumatic Systems

Yes, jaw couplings can be used in both hydraulic and pneumatic systems to connect the driving and driven components. Jaw couplings are versatile and well-suited for various power transmission applications, including those involving fluid-based systems. Here's how jaw couplings are compatible with hydraulic and pneumatic systems:

- Flexibility: Jaw couplings are made of flexible materials, such as elastomers, which allow for some angular, parallel, and axial misalignment between the shafts. In hydraulic and pneumatic systems, where vibrations and movements are common, the jaw coupling's ability to accommodate misalignment helps reduce stress on the connected components.

- Shock Absorption: Hydraulic systems often experience pressure surges and hydraulic shocks due to rapid changes in fluid flow. Similarly, pneumatic systems may encounter air pressure fluctuations. Jaw couplings can absorb shocks and vibrations, protecting the system from sudden jolts and minimizing wear on components.

- Corrosion Resistance: Some jaw couplings are available in materials that offer excellent corrosion resistance, making them suitable for hydraulic systems working with hydraulic fluids and pneumatic systems handling compressed air, which may contain moisture.

- Low Inertia: Jaw couplings have low inertia, which is advantageous in applications where quick start-stop responses are required. This characteristic is beneficial in hydraulic and pneumatic systems that need rapid and precise movements.

- Backlash Prevention: Backlash, which can lead to vibrations and inaccuracies, is minimized with jaw couplings. This feature is beneficial in hydraulic and pneumatic systems where precise positioning is crucial.

- Simple Installation: Jaw couplings are easy to install and require minimal maintenance, making them suitable for various hydraulic and pneumatic applications.

- Compatibility with Shaft Sizes: Jaw couplings are available in different sizes and configurations, allowing for compatibility with various shaft diameters commonly found in hydraulic and pneumatic systems.

Overall, jaw couplings offer reliable power transmission in hydraulic and pneumatic systems, providing benefits such as flexibility, shock absorption, corrosion resistance, low inertia, and backlash prevention. However, it's essential to consider factors such as operating conditions, temperature, and the type of fluid used when selecting a jaw coupling for a specific hydraulic or pneumatic application.

Can jaw couplings be used in heavy-duty applications such as mining and construction?

Yes, jaw couplings can be used in heavy-duty applications such as mining and construction, but their suitability depends on various factors. Jaw couplings are commonly employed in a wide range of industrial applications due to their versatility and ability to handle misalignment. However, when considering their usage in heavy-duty environments, several important aspects need to be taken into account:

- Torque and Power Requirements: Heavy-duty applications often involve high torque and power demands. It is crucial to ensure that the selected jaw coupling is rated to handle the specific torque and power levels encountered in the mining and construction machinery. Choosing a coupling with a sufficient torque capacity ensures reliable power transmission without premature failure.

- Material Strength: The materials used in the construction of jaw couplings play a critical role in their ability to withstand heavy-duty applications. Couplings made from robust materials, such as high-strength steel or alloy materials, are better suited for withstanding the demanding conditions found in mining and construction equipment.

- Impact and Shock Resistance: Mining and construction applications involve significant levels of impact and shock loads due to the nature of the work. The jaw coupling must be designed to handle these dynamic loads without compromising its structural integrity. Some jaw couplings feature specially designed elastomers or flexible elements that provide additional shock absorption and reduce the transmitted impact forces.

- Dust and Debris Management: Heavy-duty environments like mining and construction sites often contain high levels of dust, dirt, and debris. These particles can accumulate on the coupling surfaces and lead to premature wear and reduced performance. Selecting jaw couplings with appropriate sealing mechanisms or protective covers can help minimize the ingress of contaminants and extend the coupling's life in such environments.

- Maintenance and Inspection: Regular maintenance and inspection are crucial in heavy-duty applications to identify any signs of wear, misalignment, or damage to the coupling. Proper maintenance practices can prevent unexpected failures and ensure the equipment operates efficiently and safely.

When considering the use of jaw couplings in heavy-duty applications like mining and construction, it is essential to consult with coupling manufacturers or engineering experts to select the appropriate coupling type and size for the specific application. Some heavy-duty applications might require more specialized coupling designs, such as grid couplings, gear couplings, or disc couplings, which are explicitly engineered for extreme conditions and higher torque capacities. Additionally, following the manufacturer's guidelines and recommendations for coupling installation, maintenance, and operating parameters is critical to ensure reliable and safe operation in heavy-duty environments.

Use of Jaw Couplings in Various Industries for Power Transmission

Jaw couplings are widely used in different industries for power transmission due to their many advantages, including their ability to handle misalignment, shock loads, and vibrations. Some of the industries that commonly use jaw couplings include:

- Manufacturing: Jaw couplings are extensively used in manufacturing machinery such as conveyors, mixers, and packaging equipment.

- Automotive: In the automotive industry, jaw couplings are employed in various applications, including engine-driven accessories and conveyor systems in assembly lines.

- Agriculture: Farming equipment, such as tractors and harvesting machines, often use jaw couplings to transmit power from the engine to different attachments.

- Material Handling: Jaw couplings are found in material handling equipment like forklifts, cranes, and hoists.

- Water and Wastewater: Pumps and compressors used in water and wastewater treatment plants frequently utilize jaw couplings for power transmission.

- Food and Beverage: Jaw couplings are used in food processing machinery where cleanliness, reliability, and flexibility are essential.

- Textile: Textile manufacturing equipment, such as looms and spinning machines, often use jaw couplings to transmit power from motors to various components.

- Packaging: Packaging machines and equipment benefit from jaw couplings' ability to absorb shocks and vibrations.

- Printing: Printing presses and related machinery commonly use jaw couplings for their precise power transmission.

These are just a few examples, but jaw couplings are found in numerous other industries where power transmission and motion control are critical aspects of the equipment's operation. Their ease of installation, maintenance, and high-performance capabilities make them a popular choice for a wide range of applications.

editor by CX 2024-04-03