Product Description

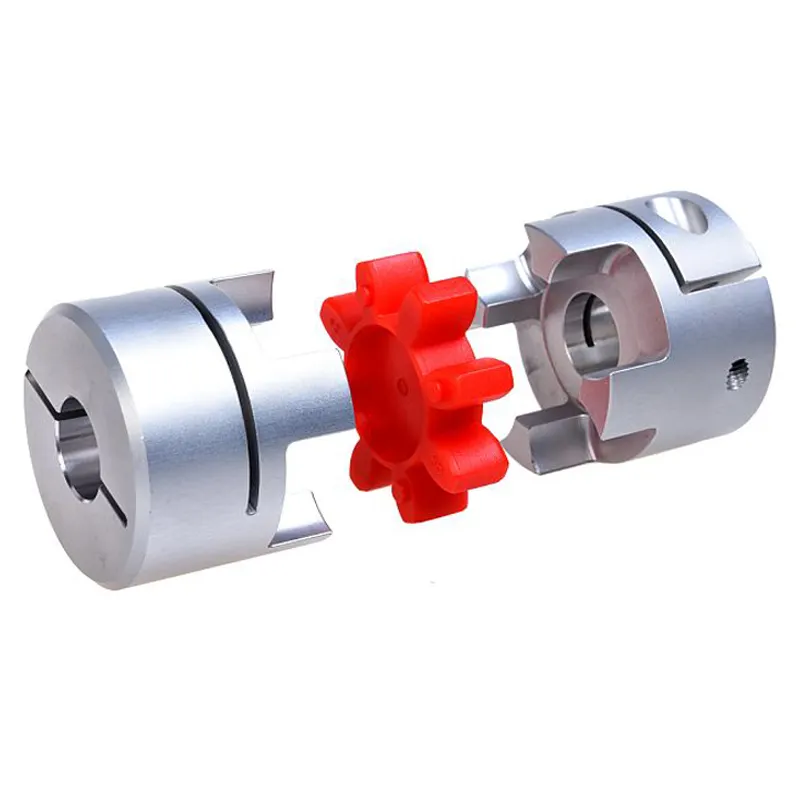

CHINAMFG Jaw couplings are designed as 3 piece comination, including 2 hubs and 1 elastomer made of polyurethane. The cuved jaw fits CHINAMFG the spider, which minimizes shock to the motor and other sensitive equipment.

Widely used in various mechanical and hydraulic fields

High precision in transmission and high rotating speed.

Suitable for wide range of environment, with the higest temperature 280 degree

Good elasticity, hight strength, corrosion resistant, wearable

No need to lubricate, quiet operation

Quick and easy mounting and disassembly

| Item No. | Finished bore range | Outside Diameter | Nominal Torque Nm |

| UTJC-14 | 0-16 | 30 | 15 |

| UTJC-19 | 0-25 | 40 | 20 |

| UTJC-24 | 0-35 | 55 | 70 |

| UTJC-28 | 0-40 | 65 | 190 |

| UTJC-38 | 0-48 | 80 | 380 |

| UTJC-42 | 0-55 | 95 | 530 |

| UTJC-48 | 0-62 | 105 | 620 |

| UTJC-55 | 0-74 | 120 | 820 |

| UTJC-65 | 0-80 | 135 | 1250 |

| UTJC-75 | 0-95 | 160 | 2560 |

| UTJC-90 | 0-110 | 200 | 4800 |

Ubet Jaw coupling grooving type is backlash free, using screws after slotting to eliminate the clearance. This grooving type coupling is suitable for power transmission on main shaft, elevating platform and machine tool.

Material: Alluminum for size below 42

Steel for size over 42

Finish: Natural or Anodizing

Size Range: 19 to 75

Finished bore: according to ISO fit H7

Keyway width: according to DIN 6885/1

The Tolerance of keyway is Js9

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Using Jaw Couplings in Hydraulic and Pneumatic Systems

Yes, jaw couplings can be used in both hydraulic and pneumatic systems to connect the driving and driven components. Jaw couplings are versatile and well-suited for various power transmission applications, including those involving fluid-based systems. Here's how jaw couplings are compatible with hydraulic and pneumatic systems:

- Flexibility: Jaw couplings are made of flexible materials, such as elastomers, which allow for some angular, parallel, and axial misalignment between the shafts. In hydraulic and pneumatic systems, where vibrations and movements are common, the jaw coupling's ability to accommodate misalignment helps reduce stress on the connected components.

- Shock Absorption: Hydraulic systems often experience pressure surges and hydraulic shocks due to rapid changes in fluid flow. Similarly, pneumatic systems may encounter air pressure fluctuations. Jaw couplings can absorb shocks and vibrations, protecting the system from sudden jolts and minimizing wear on components.

- Corrosion Resistance: Some jaw couplings are available in materials that offer excellent corrosion resistance, making them suitable for hydraulic systems working with hydraulic fluids and pneumatic systems handling compressed air, which may contain moisture.

- Low Inertia: Jaw couplings have low inertia, which is advantageous in applications where quick start-stop responses are required. This characteristic is beneficial in hydraulic and pneumatic systems that need rapid and precise movements.

- Backlash Prevention: Backlash, which can lead to vibrations and inaccuracies, is minimized with jaw couplings. This feature is beneficial in hydraulic and pneumatic systems where precise positioning is crucial.

- Simple Installation: Jaw couplings are easy to install and require minimal maintenance, making them suitable for various hydraulic and pneumatic applications.

- Compatibility with Shaft Sizes: Jaw couplings are available in different sizes and configurations, allowing for compatibility with various shaft diameters commonly found in hydraulic and pneumatic systems.

Overall, jaw couplings offer reliable power transmission in hydraulic and pneumatic systems, providing benefits such as flexibility, shock absorption, corrosion resistance, low inertia, and backlash prevention. However, it's essential to consider factors such as operating conditions, temperature, and the type of fluid used when selecting a jaw coupling for a specific hydraulic or pneumatic application.

How do jaw couplings handle axial movement in rotating machinery?

Jaw couplings are primarily designed to handle angular and parallel misalignment between rotating shafts. While they are not specifically designed for axial movement compensation, they can accommodate a limited amount of axial movement under certain conditions.

The ability of a jaw coupling to handle axial movement depends on the specific design of the coupling and the type of elastomer spider used. The elastomer spider serves as the flexible element between the two coupling hubs and is responsible for transmitting torque and compensating for misalignment. Some jaw couplings have an elastomer spider with axial flexibility, allowing the coupling to accommodate minor axial movements while maintaining effective torque transmission.

However, it is essential to note that jaw couplings have limitations regarding axial movement. They are not designed for significant axial loads or axial displacements. Excessive axial movement can lead to premature wear and damage to the elastomer spider, reducing the coupling's performance and lifespan.

If an application requires significant axial movement compensation, other types of couplings may be more suitable. For instance, flexible beam couplings or bellows couplings are designed specifically to handle axial movement and are often used in applications where axial misalignment is a critical consideration.

In summary, while jaw couplings can handle a certain amount of axial movement, they are primarily intended for angular and parallel misalignment compensation. For applications with significant axial movement requirements, it is essential to consider coupling types explicitly designed for this purpose.

Advantages of Using Jaw Couplings in Mechanical Systems

Jaw couplings offer several advantages in mechanical systems:

- Misalignment Compensation: Jaw couplings can tolerate angular, parallel, and axial misalignments between connected shafts, reducing the need for precise alignment during installation.

- Vibration Damping: The elastomeric spider in the jaw coupling absorbs shocks and vibrations, providing smoother operation and extending the life of connected equipment.

- Backlash-Free: Due to the tight fit between the jaws and the spider, jaw couplings are virtually backlash-free, enabling more accurate and responsive motion transfer.

- High Torque Capacity: Jaw couplings can handle high torque loads, making them suitable for a wide range of industrial applications.

- Easy Installation: With a simple design and few components, jaw couplings are easy to install and maintain.

- Cost-Effective: Compared to other types of couplings, jaw couplings are relatively cost-effective, providing reliable power transmission at a lower cost.

- Fail-Safe Design: In the event of a spider failure, the jaws can still maintain some torque transmission, allowing for limited operation and preventing sudden breakdowns.

Due to these advantages, jaw couplings are widely used in pumps, motors, fans, and various industrial machinery where misalignment, vibration, and torque transmission are critical factors.

editor by CX 2024-05-10