Product Description

Product Description

Steel flexible joint is also called clamp, open expansion joint, steel flexible pipe joint. Steel flexible joint is a kind of pipe connection, reliable performance, easy to install products. At low pressure, by the elastic deformation of the sealing ring, to achieve the purpose of sealing; When the pressure increases, the medium acts on the sealing ring to play the role of self-sealing, and there is a gap between the pipe ends to compensate for the displacement and deflection of the pipe caused by thermal expansion and cold contraction.

The working temperature of the clamp joint is generally -30ºC-+130ºC. The medium property is weak acid, weak alkali and lubricating oil range can be applied. If beyond the above range can also provide our company with the nature of the medium parameters or optional parameters or optional specified rubber ring material. In addition to the connection function, the joint can also provide compensation, withstand axial force, provide Angle, reduce vibration wave, adapt to the change of foundation.

The advantages of clamp joint:

1 Clamp joint has good continuity, will not produce distortion, easy to achieve the ideal laying state.

2 Clamp pipe joint in a free state, do not bear the weight of the pipe, not subjected to external shear, especially DN200 pipe diameter, more must consider the weight of the pipe.

3. It is easy to keep the coaxial position when installing the clamp joint to ensure the uneven distribution of the radial clearance between the inner diameter of the pipe clamp and the outer diameter of the pipe. The rubber ring will be deformed under high pressure due to the large local clearance, which will affect the sealing effect and even destroy the rubber ring.

4. It is suitable for the application in the subsidence zone, which can reduce the Angle between the pipe segments caused by the subsidence of the support pier.

5 is conducive to pipeline maintenance. Turn the pipe, save labor and effort when changing the pipe.

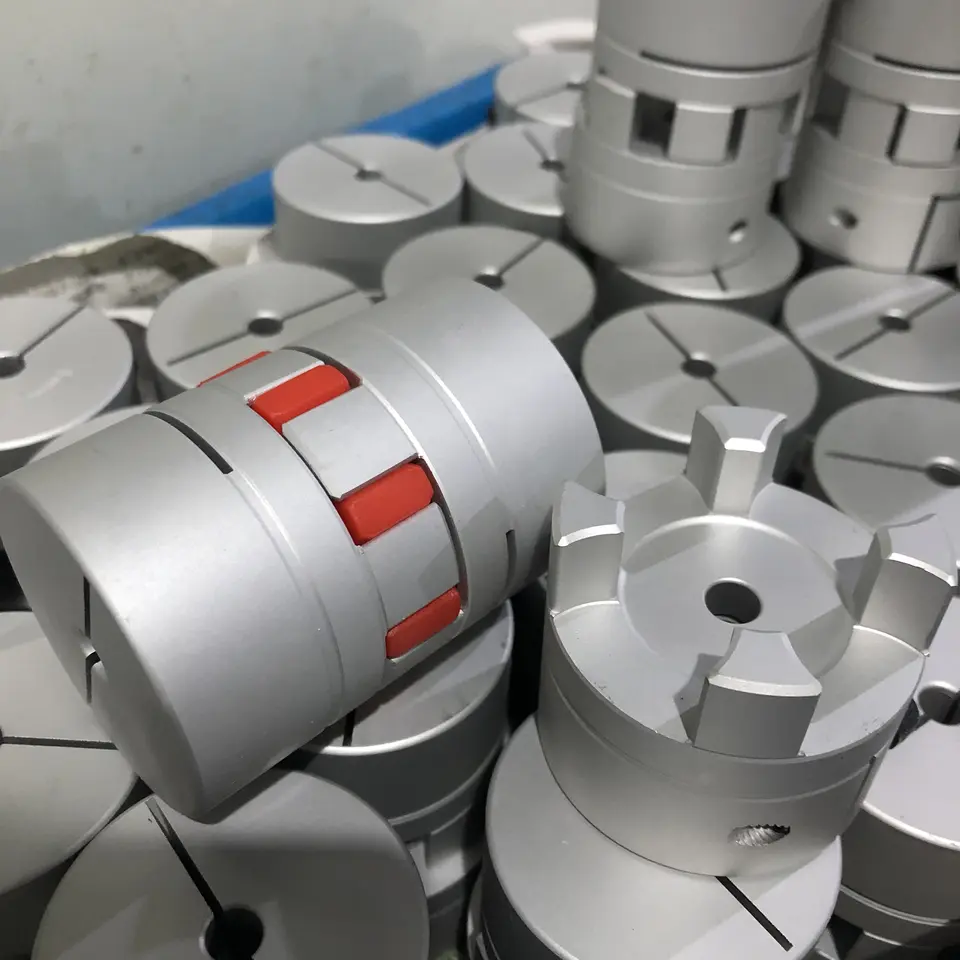

Detailed Photos

Product Parameters

PN1.6/2.5/4.0/6.4MPa KRHD

| DN(mm) | Dw(mm) | Allowable Angle Φ |

Installation length L (mm) |

Maximal length (mm) |

Fitting bolt d×L (mm) |

| 80 | 89 | 17.90 | 100 | 110 | M12*60 |

| 100 | 108 | 15.06 | 100 | 110 | M14*60 |

| 125 | 133 | 13.05 | 105 | 115 | M14*60 |

| 150 | 159 | 12.09 | 110 | 120 | M14*60 |

| 175 | 194 | 10.51 | 110 | 120 | M16*60 |

| 200 | 219 | 9.33 | 116 | 126 | M16*75 |

| 225 | 245 | 8.36 | 122 | 132 | M16*80 |

| 250 | 273 | 7.51 | 127 | 137 | M18*90 |

| 300 | 325 | 6.32 | 130 | 140 | M18*100 |

| 350 | 377 | 5.45 | 135 | 145 | M18*100 |

| 400 | 426 | 4.80 | 140 | 150 | M18*110 |

| 450 | 480 | 4.28 | 145 | 155 | M18*110 |

| 500 | 530 | 3.88 | 150 | 160 | M18*120 |

| 600 | 630 | 3.27 | 155 | 165 | M18*120 |

| 700 | 720 | 2.86 | 160 | 170 | M20*120 |

| 800 | 820 | 2.51 | 165 | 175 | M20*130 |

| 900 | 920 | 2.24 | 170 | 180 | M20*130 |

| 1000 | 1571 | 2.02 | 175 | 185 | M20*130 |

| 1200 | 1220 | 1.69 | 180 | 190 | M22*140 |

| 1400 | 1420 | 1.45 | 185 | 195 | M22*140 |

| 1600 | 1620 | 1.27 | 190 | 200 | M22*140 |

| 1800 | 1820 | 1.13 | 195 | 205 | M22*150 |

| 2000 | 2571 | 1.01 | 200 | 210 | M24*150 |

| 2200 | 2571 | 1.01 | 205 | 215 | M24*150 |

| 2400 | 2420 | 1.01 | 210 | 220 | M24*150 |

| 2600 | 2620 | 1.01 | 215 | 225 | M24*160 |

| 2800 | 2830 | 1.01 | 220 | 230 | M27*160 |

| 3000 | 3571 | 1.01 | 225 | 230 | M27*160 |

| 3200 | 3220 | 1.01 | 230 | 240 | M27*180 |

Datas above are only for reference,if you want to know more details, please click here to contact us.

Installation Instructions

1. Prepare groove pipe sections, fittings and accessories that meet the requirements.

2. Check whether the rubber sealing ring is damaged and put it on the end of a steel pipe.

3. There should be a certain gap between the end and both ends of the steel pipe close to the end and both ends of the pipe which has been covered with rubber sealing ring. The clearance shall meet the standard requirements.

4. Put the rubber seal ring on the end of another steel pipe, make the rubber seal ring in the middle of the interface, and apply lubricant on the same side.

5. Check the axis of the pipe.

6. Install upper and lower clamps on the outer side of rubber seal-ing ring at the interface position, and clip the collar convex edge into the groove.

7. Press the upper and lower clamp ears with hand force, tighten the collar of the clamp with a wooden hammer, and tighten the upper and lower clamps tightly.

8. At the clamp screw hole position, put on the studs and tighten the nuts evenly to prevent the rubber sealing ring from wrin-kling.

9. check and comfirm that the collar convex edge is clamped into the groove.

products application

Company Profile

HangZhou Ruixuan pipeline equipment factory was founded in 1996.It is an excellent enterprise specializing in manufacturing and selling pipe fittings.It's located in Xicun village ,HangZhou city,ZheJiang province ,the concentrated area of pipeline equipment industry in China.The company factory is located in Xicun town pipeline equipment industrial park.It covered an area of20000 square meters.

At present, the company has the production capacity of pipeline equipment with a maximum diameter of 4000mm, and its main products are: Steel expansion joint, flexible waterproof sleeve, large diameter flange, double flange force transfer expansion joint, large deflection loose sleeve compensation joint, spherical compensation joint, sleeve compensator, bellows compensator, non-metallic compensator, rubber expansion joint, DC medium no thrust sleeve compensator, flexible expansion pipe and other pipeline equipment. The annual production capacity is 30 million sets.

The flexible telescopic pipe equipment is mainly used in the pipeline crossing different geological structures under different conditions and the application of pipe installation drop, reduce or avoid the impact of geological settlement and crustal activity on the pipeline, so that the construction unit can save more than 50% of the cost when purchasing the equipment. The rubber expansion joint series products of the company, the maximum production diameter of 3600mm, have been applied in millions of units of thermal power projects in China for many times, and have been praised by the users.

The company passed ISO9001:2008 quality management system certification in 2009 and ISO14000:2004 environmental management system certification in 2009. The company has a strict quality control system, standard production process, standard factory inspection hand section, to ensure that every product meets the national standards and customer requirements.

Business philosophy: responsible production of products, return the trust of customers; To build a community with a sense of belonging and appreciate employees' contributions; Make a contribution to the society of enterprises, give back to the good times. HangZhou Ruixuan pipeline equipment factory is willing to work with friends from all walks of life hand in hand, mutual support, create a better future!

Certifications

FAQ

Q:Can you make the product as per client's requirement?

A:Yes, we can make it with your exact requirement.

Q:What are your payment terms?

A:T/T (30% as deposit, the rest 70% will be paid before delivery), L/C at sight.

Q:Where is your nearest loading port?

A:ZheJiang , HangZhou or ZheJiang , China.

Q:How can you guarantee the quality or any warranty?

A:If any quality problems during use, all the products can be returned or according to consumer's requests.

Q:Do you accept small quantity order?

A:Of course we do.

Q:And what is your shipment and delivery time?

A:By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

Torque and Speed Ratings for Different Sizes of Jaw Couplings

The torque and speed ratings for jaw couplings vary depending on their size and design. Manufacturers typically provide specifications for different sizes of jaw couplings, and it's essential to select the appropriate coupling based on the specific requirements of the application. Here's how torque and speed ratings are determined for jaw couplings:

- Torque Rating: The torque rating of a jaw coupling is the maximum amount of torque it can transmit without causing failure. It is typically specified in Newton-meters (Nm) or inch-pounds (in-lb). Larger jaw couplings generally have higher torque ratings than smaller ones, as they can accommodate more substantial loads.

- Speed Rating: The speed rating of a jaw coupling refers to the maximum rotational speed at which it can operate efficiently and reliably. It is usually specified in revolutions per minute (RPM). Higher-speed applications may require jaw couplings designed to handle increased rotational velocities.

It's essential to carefully match the torque and speed requirements of the application with the appropriate jaw coupling size. Undersized couplings may result in premature failure, while oversized couplings might lead to reduced flexibility and increased wear. Manufacturers' catalogs or product datasheets provide detailed information on the torque and speed ratings for each coupling size, helping engineers and designers make informed decisions when selecting the right coupling for their specific needs.

Can jaw couplings be used in pumps, compressors, and fans?

Yes, jaw couplings can be used in pumps, compressors, and fans, and they are commonly employed in these types of rotating equipment. Jaw couplings offer several advantages that make them well-suited for these applications:

- Misalignment Compensation: Pumps, compressors, and fans often experience misalignment between the motor and driven equipment due to various factors such as installation errors, thermal expansion, or shaft deflection. Jaw couplings can handle both angular and parallel misalignment, ensuring smooth power transmission and reducing the risk of premature wear on the equipment's bearings.

- Vibration Damping: Pumps, compressors, and fans can generate significant vibrations during operation. The elastomer spider in the jaw coupling acts as a damping element, absorbing and dissipating vibrations. This feature helps to reduce noise, extend the life of the equipment, and enhance overall system reliability.

- Torsional Flexibility: Jaw couplings provide torsional flexibility, which is beneficial in applications where the motor and driven equipment experience varying loads or torque spikes. The elastomer spider allows for slight torsional deflection, protecting the equipment from sudden shock loads and torque fluctuations.

- Compact and Lightweight: Pumps, compressors, and fans often have space constraints, and jaw couplings are compact and lightweight compared to some other coupling types. Their reduced inertia makes them suitable for applications with frequent start-stop cycles and high-speed operation.

Jaw couplings are available in various sizes and materials, allowing for customization based on the specific requirements of the pump, compressor, or fan application. The proper selection of a jaw coupling ensures optimal performance and efficiency in these rotating equipment systems.

However, it is essential to consider the specific operating conditions and torque requirements of each application when choosing a jaw coupling. For certain heavy-duty or high-precision applications, alternative coupling types such as gear couplings or disc couplings might be more suitable. It is always advisable to consult coupling manufacturers or engineering experts to select the most appropriate coupling for a given application.

Safety Considerations When Using Jaw Couplings in Rotating Machinery

While jaw couplings are generally safe to use in rotating machinery, there are some important safety considerations to keep in mind to ensure safe and reliable operation:

- Proper Installation: Correct installation is crucial for the safe functioning of jaw couplings. The coupling should be mounted precisely in alignment with the shafts to prevent misalignment and minimize stress on the components.

- Regular Maintenance: Regular inspection and maintenance are essential to identify signs of wear, misalignment, or damage. Any issues should be addressed promptly to prevent potential failures that may compromise safety.

- Load Capacity: Ensure that the selected jaw coupling has an adequate load capacity for the specific application. Overloading the coupling can lead to premature failure and safety risks.

- Operating Speed: Be mindful of the operating speed limitations of the jaw coupling. Operating the coupling beyond its maximum rated speed may result in excessive wear and potential hazards.

- Environmental Factors: Consider the environmental conditions in which the jaw coupling will operate. Extreme temperatures, humidity, or corrosive substances may impact the coupling's performance and longevity.

- Emergency Shutdown: Implement an emergency shutdown procedure to quickly stop the machinery in case of any unexpected issues or safety concerns.

- Guarding and Enclosure: Depending on the application, consider using protective guarding or enclosures to prevent accidental contact with rotating components and ensure operator safety.

- Compliance with Standards: Follow industry standards and regulations relevant to the specific application to ensure compliance and adherence to safety guidelines.

By adhering to these safety considerations, operators and maintenance personnel can help minimize the risk of accidents, protect personnel from potential hazards, and ensure the reliable and safe operation of rotating machinery with jaw couplings.

editor by CX 2023-09-21