Product Description

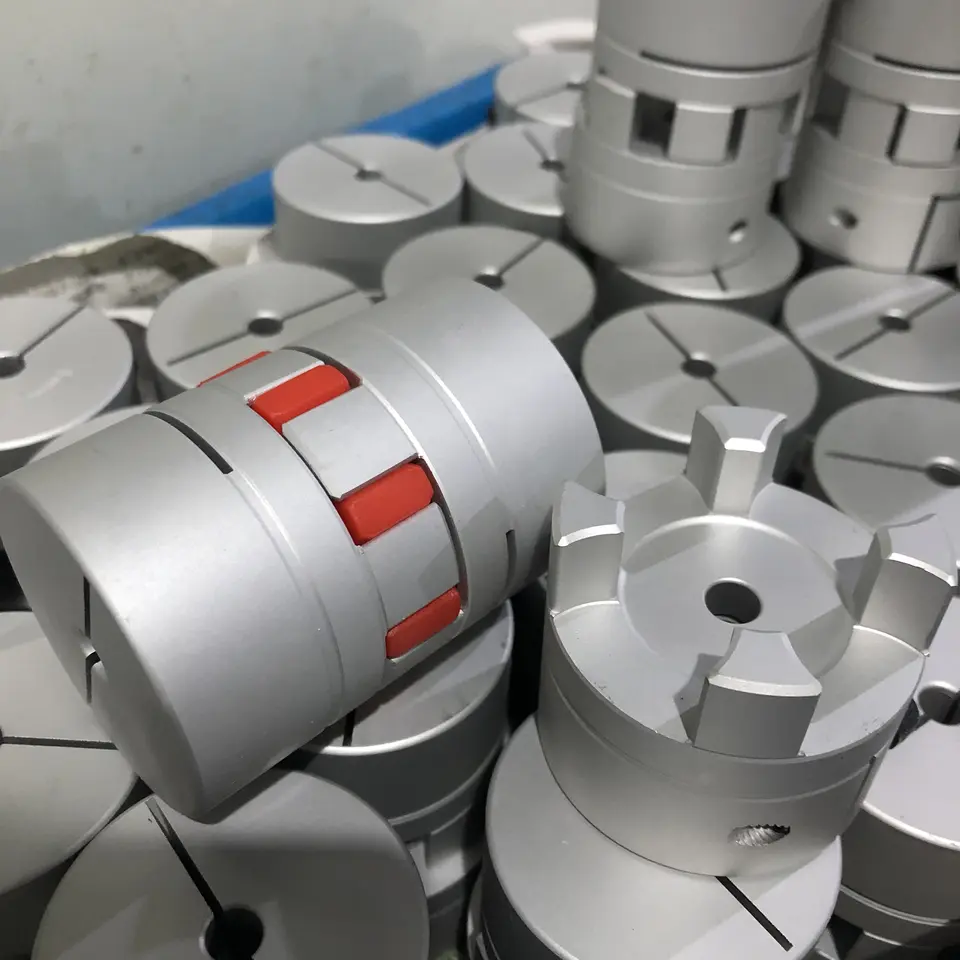

Couplings:

1. The couplings offer a range of hub and element selection to meet different demands.

2. They can absorb shock and cater for incidental misalignment and damp out small amplitude vibrations.

3. NBR, Urethane, Hytrel elements.

4. Customized requirement is available.

Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

PACKING

| Packaging | |

| Packing

|

We use standard export wooden case, carton and pallet, but we can also pack it as per your special requirements. |

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years' hard work, MIGHTY's business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY's products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Torque and Speed Ratings for Different Sizes of Jaw Couplings

The torque and speed ratings for jaw couplings vary depending on their size and design. Manufacturers typically provide specifications for different sizes of jaw couplings, and it's essential to select the appropriate coupling based on the specific requirements of the application. Here's how torque and speed ratings are determined for jaw couplings:

- Torque Rating: The torque rating of a jaw coupling is the maximum amount of torque it can transmit without causing failure. It is typically specified in Newton-meters (Nm) or inch-pounds (in-lb). Larger jaw couplings generally have higher torque ratings than smaller ones, as they can accommodate more substantial loads.

- Speed Rating: The speed rating of a jaw coupling refers to the maximum rotational speed at which it can operate efficiently and reliably. It is usually specified in revolutions per minute (RPM). Higher-speed applications may require jaw couplings designed to handle increased rotational velocities.

It's essential to carefully match the torque and speed requirements of the application with the appropriate jaw coupling size. Undersized couplings may result in premature failure, while oversized couplings might lead to reduced flexibility and increased wear. Manufacturers' catalogs or product datasheets provide detailed information on the torque and speed ratings for each coupling size, helping engineers and designers make informed decisions when selecting the right coupling for their specific needs.

What are the factors influencing the thermal performance of a jaw coupling?

The thermal performance of a jaw coupling is influenced by several factors that affect its ability to dissipate heat and handle temperature fluctuations during operation. Here are the key factors that can impact the thermal performance of a jaw coupling:

- Material Selection: The choice of materials used in the construction of the jaw coupling plays a significant role in its thermal performance. High-quality materials with good thermal conductivity can efficiently dissipate heat, reducing the risk of overheating and premature wear. Common materials used in jaw couplings include steel, aluminum, and various elastomers.

- Elastomer Spider: The elastomer spider in the jaw coupling is a crucial component that can influence thermal performance. The type of elastomer and its specific characteristics, such as hardness and thermal conductivity, can affect the coupling's ability to absorb and dissipate heat generated during operation.

- Operating Speed: The rotational speed of the coupling impacts its thermal performance. Higher operating speeds can generate more heat due to increased friction and stress on the coupling components. It is essential to ensure that the jaw coupling is rated for the specific operating speed of the application to prevent overheating and premature failure.

- Torque and Load: The torque and load applied to the jaw coupling can also influence its thermal performance. Higher torque and load levels can result in increased heat generation. Properly sizing the coupling based on the application's torque and load requirements is essential to prevent excessive heat buildup.

- Operating Environment: The environment in which the jaw coupling operates can impact its thermal performance. For example, if the coupling is located in an area with limited airflow or high ambient temperatures, it may experience reduced heat dissipation capabilities. On the other hand, an environment with good ventilation can help in maintaining the coupling's thermal performance.

- Lubrication: Some jaw couplings may require lubrication to reduce friction and heat generation. Proper lubrication can enhance the coupling's thermal performance and extend its service life. It is essential to follow the manufacturer's guidelines regarding the type and frequency of lubrication to ensure optimal performance.

- Continuous vs. Intermittent Operation: The thermal performance of a jaw coupling can also be influenced by the nature of its operation—continuous or intermittent. Intermittent operation allows the coupling to cool down between cycles, reducing the overall heat buildup compared to continuous operation, which may lead to higher operating temperatures.

Overall, careful consideration of these factors is crucial in ensuring the efficient thermal performance of a jaw coupling. Proper selection, installation, and maintenance of the coupling based on the specific application requirements can help prevent overheating, reduce wear, and prolong the coupling's lifespan.

Materials Used in Manufacturing Jaw Couplings

Jaw couplings are commonly made from various materials, each offering different properties and suitability for specific applications. Some of the commonly used materials include:

- Polyurethane (PU): PU jaw couplings are known for their flexibility, high elasticity, and resistance to abrasion. They are ideal for applications requiring vibration dampening and shock absorption.

- Aluminum: Aluminum jaw couplings are lightweight, corrosion-resistant, and have good thermal conductivity. They are commonly used in low-to-medium torque applications.

- Steel: Steel jaw couplings offer high strength and durability, making them suitable for heavy-duty applications with high torque requirements.

- Stainless Steel: Stainless steel jaw couplings are resistant to corrosion and are often used in applications where there is exposure to moisture, chemicals, or harsh environments.

- Bronze: Bronze jaw couplings are known for their excellent wear resistance and low coefficient of friction, making them suitable for applications with high-speed and low lubrication.

- Acetal: Acetal jaw couplings provide good chemical resistance and low moisture absorption, making them suitable for applications where chemical exposure is a concern.

- Nylon: Nylon jaw couplings offer good strength, flexibility, and resistance to wear and chemicals, making them suitable for various industrial applications.

The choice of material depends on factors such as torque requirements, environmental conditions, operating speeds, and budget considerations. Engineers and designers select the appropriate material to ensure that the jaw coupling can perform optimally and withstand the demands of the application.

editor by CX 2023-08-09